Making the Elgin Grade 367 - Father Time

Making the Elgin Grade 367 - Father Time |

|

|

The Elig grade 367, "Father Time", is a classic high-grade "railroad watch". It is an 18 size, lever-set, adjusted, 21 jewel time piece with impressive features and finish. These photos have been left a little on the large size to show more of detail on this fine example. The Father Time movements are Elgin's top of the line products. This fine 21 jewel watch was made in 1910, serial number 15154313. It is in an ore silver swing-out, open-face case. It came to me for cleaning, and a new crystal. |

|

|||

|

The dial and hands are in good condition, but show some signs of age. There was some small chipping around the left side of center hole. This image shows the dial after I've done a little enamel repair of the area. |

|

|||

|

Here is a before and after of the dial showing the enamel repair. |

|

|||

|

|

|

|||

|

Dial, removed, this dail shows the setting lever mechanism. There a bridge and it's screw sitting on the plate that have been removed to show the wheels.

|

|

|||

|

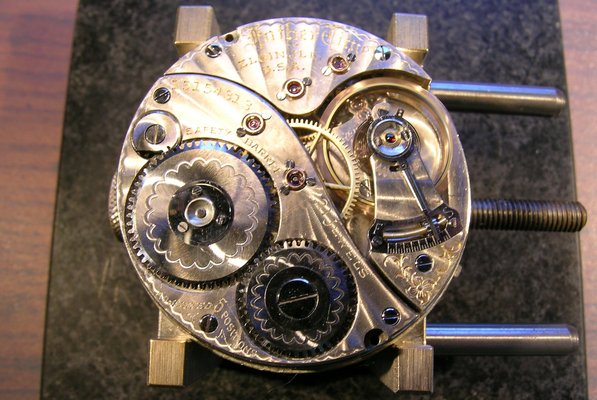

Here is the movement ready for disassembly. Note the micro-regulator on the balance bridge. The watch was running when this photo was taken, as can be seen in the motion of the balance wheel. |

|

|||

|

"Father Time" |

|

|||

|

Note the gold jewel settings and detailed plate finishing. This photo also shows the rounded and polished arms of the center wheel. All the wheels of this watch are finished in gold except the escape which is steel. |

|

|||

|

The lever, which features large counter balance "wings", is also well finished with beveled and polished edges. |

|

|||

|

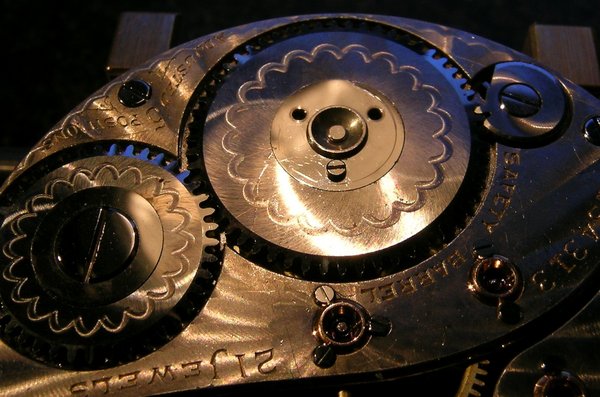

This watch has a "motor barrel" in which the top half is attached to the rachet wheel with screws. Here two of the three screws are removed. With a moter barrel, the entire top half of the barrel turns separately from the lower half for winding. In a typical barrel the entire barrel turns as one piece for power, and for winding the mainspring arbor turns alone. |

|

|||

|

Here is futher detail of the top-side winding parts. |

|

|||

|

|

|

|||

|

This is a 21 jewel timepiece. The upper and lower escape and balance jewels have caps - there is both a pivot jewel with a hole for the end of the wheel staff, and a cap jewel (no hole) covering it. Everthing gets disassembled for cleaning. |

|

|||

|

|

|

|||

|

Here we can see the motor barrel. Note how the driving part (lower) of the barrel is separate from the upper (winding) part. The arbor in this barrel is hard-fixed to the lower part and does not rotate independently for winding. The end of the spring is hooked to the upper part. |

|

|||

|

|

|

|||

|

The winding ardor and clutch parts... |

|

|||

|

The train and balance wheels... |

|

|||

|

Here's the basic components after cleaning, assembling the motor barrel and replacing and polishing the jewels. |

|

|||

|

High grade watches like this one are made from the best materials and parts to an especially high tolerance. There is a noticable differance in how how smoothly the parts work together, how nicely the watch assembles, and even how it sounds when running. More watches here... |

|

|||

|

||||

|

|

||

|

|

|||

Comments to jsexton@elgintime.com